A good packaging artwork and its importance

A good packaging artwork is essential for any product. The first thing a potential buyer notices about the product is its packaging. Many of our buying decisions are based on the visual appeal that product packages have on us. This is because we are visual creatures and this is why a good packaging artwork is one of the most essential parts of product sales. Innovative and interesting packaging will draw in more customers than one which is simple and uninteresting. However, good packaging artwork also means that with innovation it is also purposeful and creates less waste.

This is the type of packaging that companies try to achieve with their work. They try to bring this concept from the screen to real life and that is what packaging organization is. It is the combination of tools and efficient artwork management software that helps guide this development. Though it sounds like a simple process, it is actually quite complex because many designs that look creative on-screen are generally quite difficult to bring to life. Companies often make this process tedious and full of errors. This happens when good artwork management software is not used which can cause a lot of challenges.

Some of the most common mistakes in setting packaging artwork

Companies often face challenges while they develop and set their packaging artwork. The challenges they face are mostly caused by the lack of efficiency and communication which is a result of a deficiency of artwork management software. Errors and mistakes that are not picked up until too late can cause damage to the company’s reputation and also disrupt the supply chain. It can also lead to added cost due to reprints and wastage of materials. Allow us to break down probably the most well-known mix-ups in order to keep away from them.

Dot gain not accounted for

The ink laydown can be impacted by a phenomenon known as dot gain. The diameters of halftone dots can be affected during printing. They can increase and become larger with a definition that is not sharp enough. Experience and efficient reprographics are able to minimise this affect and recreate the image that is more true to the actual substrate. However, complete removal is not possible, only management is. This is why dot gain has to be accounted for during the process of designing. They also have to be delivered with linear plates. The general tolerance is or 2% and softwares options and calibration tools can help with dot gain in order to make sure that the print is true to the on screen design.

Low-resolution printing

A high-quality design is essential for the best packaging artwork that makes it on the shelf. Brands that go for in-house production and development often face the challenge of artwork that is too low in resolution. Unfortunately, many brands still take the risk and run with this low resolution print.

However, what should be done is a 1:1 design should be created. This should also match the particular dimensions of the final packaging. This can be achieved when an extra collaboration and communication is added to the supply process of the design and packaging. Another alternative is to partner up with a reprographic who can do this for you by reducing the time, errors, discrepancies and cost. With high resolution prints it is possible to avoid errors like blurry barcodes and texts and fuzzy images.

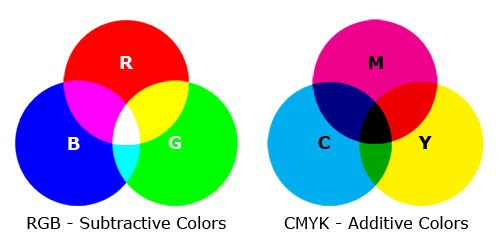

The wrong usage of colour model

Before most things can be collaboratively discussed and developed, one of the first prominent steps of packaging artwork is selecting the correct colour model. This is done before any visual or graphic is designed and before they reach at the production stages. The two most common colour models that normally designers opt for it the CMYK (cyan, magenta, yellow and black) and RGB (red, green and black)

The RGB model looks good on screen but is not able to translate that accurately on print and that is why they are mostly used for web banners, social media images and other digital graphics and displays. The CMYK model can deal with changes in tone and also create extra shades such as greens and oranges. A wide range of colours can be achieved when it is paired with spot inks or coatings. It can also help with managing changeover of inks as well as being accurate and consistent with print.

Ignoring Sustainability

One grave mistake that companies often commit is ignoring prepress which is essential for a general drive towards sustainability. Consumers now look for alternatives that are low on the carbon footprint and a digital prepress would reduce errors and also eliminate the amount of waste materials and along with decreased time and energy. Some print technologies are also very helpful in reducing the carbon footprint right in the initial stages.

As the development of packaging artwork becomes more complex it would only be a smart decision to take the help of efficient artwork management software that reduces risk of errors and challenges and increases efficiency and profit.